|

Ginde Plastic Pipe Industry Company

|

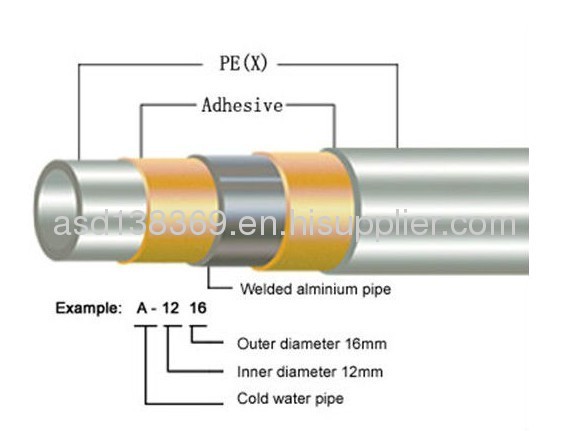

pap pipe PE-AL-PE pipe

| Payment Terms: | T/T,L/C, |

| Place of Origin: | Liaoning, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Heat conduction coefficient 0.45W/(m.k)

Heat expansion coefficient 0.025mm/(m.k)

Bent radius ≥5D(D means outside diameter)

GINDE PAP COMPOSITE PIPELINE SYSTEM

Features of PAP composite pipe

GINDE AL-PE composite pipes consist of a core aluminum with inner and outer layers of plastic, tightly bonded to the aluminum by means of a special adhesive. We adopt the extrusion technology and overlapped welded aluminum pipe. PAP has not only high pressure resistance like the metal pipe. Features of PAP composite pipe as follows:

a) Compared with the metal pipe, PAP pipe has the same strength, easy to bend, reluctant to retain former shape.

b) Super properties of high temperature, high pressure and corrosion resistance.

c) Smooth inner surface of the pipe reduces resistance to the fluids. The ability to conduct water is 30% more efficient.

d) Fire resistant property

e) Good property of heat preservation, heat conduction coefficient is 0.45W/m.k, which is much less than metal pipes and it can save insulation materials outside the pipe.

f) Ease to cut and install. It can be connected with special fittings instead of screw fittings. Small diameter pipes can be rolled and packaged. Once received the pipes (bent radius ≥5D) can be cut to desired length and simply bent in order that many directional parts such as elbows or angles are no longer necessary. Very convenient to install, much time and labor cost can be saved.

g) Lifespan of the pipe is more than fifty years.

h) Light weight, the weight is 1/10 of galvanized pipes and lower transportation fees and lower cost are reduced

i) It can be served as a cable to cover electric wires.

j) The pipe can be used as reck piping and underground piping and easily located with a metal detector.

k) The core aluminum pipe can prevent oxygen seepage to avoid the bacteria.

Applications

a) Heat and cold pipes for production and life.

b) Heating system of caliduct, underfloor and wall, the equipment for snow melting in Northern China.

c) Pipes for water engineer in residential area.

d) Piping of central air-condition and blower.

e) Piping of solar energy water heater.

f) Pipeline of coal gas and natural gas.

g) Oxygen pipeline in hospital.

h) Industrial pipelines of oil and cooling liquids.

i) Conduct of electric wire and cable.

j) Pipes for vacuum absorption.

k) Conveying potable liquids in beverage factory.

l) Pipes for irrigation engineer in agriculture and gardens.

Technical specification

Heat conduction coefficient0.45W/(m.k)

Heat expansion coefficient 0.025mm/(m.k)

Bent radius ≥5D(D means outside diameter)

Media temperature -40℃-95℃

Gas (oxygen) penetration factor 0

Inside smooth and small resistance to liquids, its roughness coefficient is only 0.0004mm

Other excellent property of static resistance and long life

Connection method of Ginde screw fitting:

l Cut pipes according to the required length

l Screw the nut and C-ring on the pipe respectively

l Bevel the open with beveller and chamfer angle

l Insert fitting into pipe completely

l Remove the C-ring to the point which is 0.5~1.5mm to the open of pipe, then screw the nut and fitting

Note: when connecting the pipeline for hot water, the fitting should be used with Ginde special adhesive, in order to improve the seal property.

Special pipe of Ginde PAP composite

PAP composite pipe with nanometer and antibacterial action

PAP composite pipe with fire resistant property

PAP composite pipe with static shield

PAP composite pipe with anti-ultraviolet radiation

Specification of Ginde PAP composite pipe

Pipe | Colour | Specification | Inside diameter | Outside diameter | Maximum of operating pressure | Maximum of operating temperature | Burst strength | Standard package | Standard weight |

Pipe for hot water | White | R1014 | 10 | 14 | 1.0 | 95 | ≥7.0 | 200 | 17.5 |

R1216 | 12 | 16 | 1.0 | 95 | ≥6.0 | 200 | 22.0 | ||

R1418 | 14 | 18 | 1.0 | 95 | ≥5.0 | 200 | 24.0 | ||

R1620 | 16 | 20 | 1.0 | 95 | ≥5.0 | 200 | 31.5 | ||

R2025 | 20 | 25 | 1.0 | 95 | ≥4.0 | 100 | 23.0 | ||

R2632 | 26 | 32 | 1.0 | 95 | ≥4.0 | 50 | 17.0 | ||

R3240 | 32 | 40 | 1.0 | 95 | ≥4.0 | 6 | 3.1 | ||

R4150 | 41 | 50 | 1.0 | 95 | ≥3.8 | 6 | 4.5 | ||

R5163 | 51 | 63 | 1.0 | 95 | ≥3.8 | 6 | 7.7 | ||

R6075 | 60 | 75 | 1.0 | 95 | ≥3.8 | 6 | 10.8 | ||

Pipe for cold water | White | L1014 | 10 | 14 | 1.0 | 60 | ≥7.0 | 200 | 17.5 |

L1216 | 12 | 16 | 1.0 | 60 | ≥6.0 | 200 | 22.0 | ||

L1418 | 14 | 18 | 1.0 | 60 | ≥5.0 | 200 | 24.0 | ||

L1620 | 16 | 20 | 1.0 | 60 | ≥5.0 | 200 | 31.5 | ||

L2025 | 20 | 25 | 1.0 | 60 | ≥4.0 | 100 | 23.0 | ||

L2632 | 26 | 32 | 1.0 | 60 | ≥4.0 | 50 | 17.0 | ||

L3240 | 32 | 40 | 1.0 | 60 | ≥4.0 | 6 | 3.1 | ||

L4150 | 41 | 50 | 1.0 | 60 | ≥3.8 | 6 | 4.5 | ||

L5163 | 51 | 63 | 1.0 | 60 | ≥3.8 | 6 | 7.7 | ||

L6075 | 60 | 75 | 1.0 | 60 | ≥3.8 | 6 | 10.8 | ||

Pipe for gas | Yellow | Q1014 | 10 | 14 | 0.4 | 40 | ≥7.0 | 200 | 17.5 |

Q1216 | 12 | 16 | 0.4 | 40 | ≥6.0 | 200 | 22.0 | ||

Q1418 | 14 | 18 | 0.4 | 40 | ≥5.0 | 200 | 24.0 | ||

Q1620 | 16 | 20 | 0.4 | 40 | ≥5.0 | 200 | 31.5 | ||

Q2025 | 20 | 25 | 0.4 | 40 | ≥4.0 | 100 | 23.0 | ||

Q2632 | 26 | 32 | 0.4 | 40 | ≥4.0 | 50 | 17.0 | ||

Q3240 | 32 | 40 | 0.4 | 40 | ≥4.0 | 6 | 3.1 | ||

Q4150 | 41 | 50 | 0.4 | 40 | ≥3.8 | 6 | 4.5 | ||

Q5163 | 51 | 63 | 0.4 | 40 | ≥3.8 | 6 | 7.7 | ||

Q6075 | 60 | 75 | 0.4 | 40 | ≥3.8 | 6 | 10.8 |

Packing defails

Pipe | Quantity/ctn | Packing Messurement | Quantity/20'FCL | Quantity/40'FCL | Weight/20'FCL | Weight /40'FCL |

1014 | 200m | 650x230x650mm | 55,400m | 115,200m | 4,542.8 kg | 9,085.6 kg |

1216 | 100m | 650x230x650mm | 27,700m | 57,600m | 3,047 kg | 6,094 kg |

1216 | 200m | 700x230x700mm | 47,800m | 99,200m | 5,258 kg | 10,516 kg |

1418 | 100m | 700x230x700mm | 23,900m | 49,600m | 3,107 kg | 6,214 kg |

1418 | 200m | 800x230x800mm | 36,600m | 76,000m | 4,578 kg | 9,516 kg |

1620 | 100m | 700x230x700mm | 23,900m | 49,600m | 3,585 kg | 7,170 kg |

1620 | 200m | 850x230x850mm | 32,400m | 67,400m | 4,860 kg | 9,720 kg |

2025 | 50m | 700x230x700mm | 11,950m | 24,800m | 2,185.2 kg | 5,162.4 kg |

2025 | 100m | 800x230x800mm | 18,300m | 38,000m | 3,952.8 kg | 7,905.6 kg |

2632 | 25m | 800x230x800mm | 4,575m | 9,500m | 1,720 kg | 3,440.4 kg |

2632 | 50m | 850x230x850mm | 8,100m | 16,850m | 3,045.6 kg | 6,091.2 kg |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

PE Pipe

Pe Pipe Machine

Pe Pipe Production Line

Pe Plastic Pipe

PE Water Pipe

Pe Pipe Extrusion Line

More>>